Resonating with Everyday Challenges

Ever felt bogged down by outdated technology that just doesn’t seem to work when you need it? We’ve all been there—those frustrating moments when everything fails at the most inconvenient times. This is especially true in the world of digital IO, where precision and adaptability are paramount. Did you know that nearly 75% of businesses struggle with outdated hardware in their operations? It’s no wonder that the quest for a seamless and efficient workflow has led to innovations like the discrete control input output device. This technology not only promises to smoothen out operations but also aligns perfectly with the dynamic nature of modern industries.

Understanding Traditional Flaws

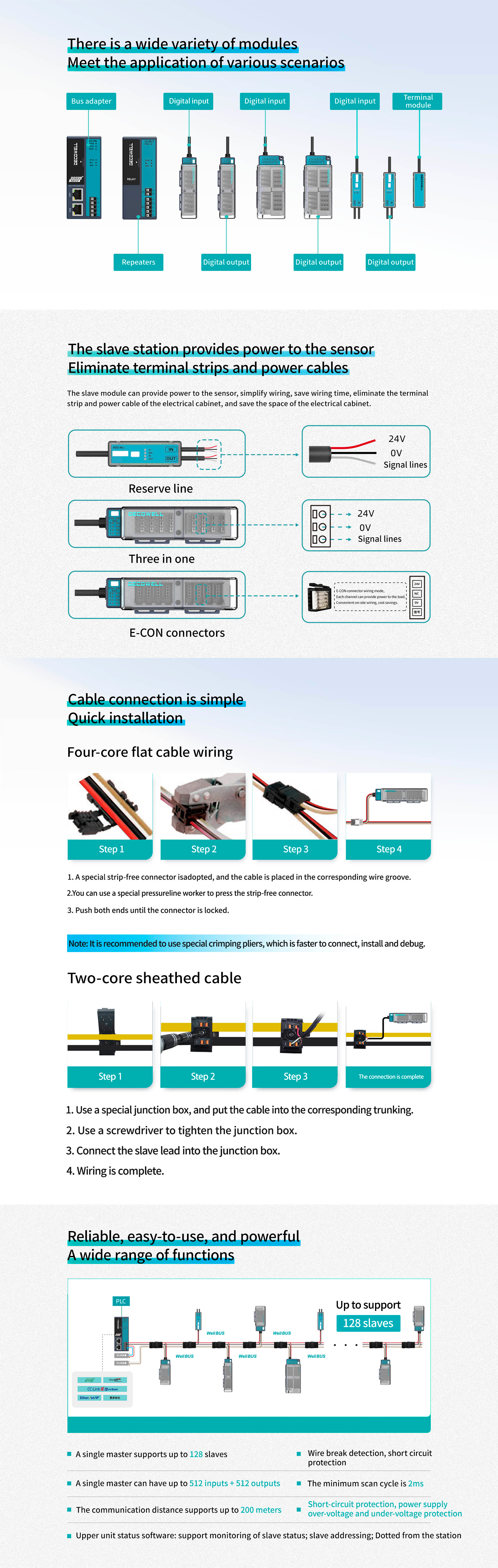

Let’s face it—traditional solutions can be a hassle. They often lack flexibility, creating bottlenecks in data processing and management. Older technologies might be reliable, but they don’t always adapt well to new requirements, leading to inefficiencies. As industries evolve, so should the devices we rely on. Enter the new era of digital control: devices that marry compatibility with powerful performance. The discrete control input output device serves as a prime example of this evolution, incorporating modern principles of connectivity and integration.

Embracing New Technologies

So, what principles are these new technologies built on? Think robust software-hardware integration, real-time data processing, and scalability. Essentially, they are designed with a modular approach that allows for easy updates and modifications—translating into cost-saving efficiencies for users. With innovations like the discrete control input output device, companies can expect smoother transitions and better performance metrics. We’re living in a time where agility is key, and these advancements help keep pace with rapidly changing market demands.

Measurable User Benefits

What can users expect, though? To paint a clearer picture, let’s talk numbers. Organizations utilizing advanced setup like the discrete control input output device have reported a boost in operational efficiency by up to 40%. This translates not just into time savings, but also tangible cost reductions and improved output quality. In short, switching to newer technology is about redefining potential, not only ensuring that you keep up but also setting the pace.

Take Action: Evaluate Wisely

When it comes to choosing the right solutions for your needs, always verify these 3 metrics: ① Compatibility with existing systems ② Scalability options ③ Cost-effectiveness over time. Evaluating these factors carefully will help you make informed decisions that align with your operational goals—because technology should work for you, not the other way around.

Maximizing Potential with the Digital IO Module

Speaking of efficiencies, have you ever delved into what the digital input/output module can do for your systems? These modules are game-changers, offering robust connectivity solutions that enhance data acquisition and control among various devices. By leveraging such advancements, industries can streamline operations significantly—leading to increased reliability and performance. The functionality of a digital input/output module bridges communication gaps effortlessly, ensuring all systems work in harmony round-the-clock.

Performance Metrics and Technological Edge

With a digital input/output module, businesses gain not only operational improvements but also higher adaptability to change. That’s right! These devices often come equipped with state-of-the-art analytics capabilities, allowing real-time monitoring and adjustments. Users can see immediate impacts, like a reduction in downtime by up to 30%, which is substantial in today’s fast-paced environment. This is where the digital input/output module shows its true potential—helping you stay ahead of the curve by providing insights that drive smart decision-making.

Summarizing Benefits and Recommendations

In summary, upgrading to a modern discrete control input output device or a digital input/output module is more than just keeping up with trends; it’s about enhancing your operational efficiencies and making your work life easier. It’s crucial to consider factors like compatibility, scalability, and long-term cost savings when making such transitions. For those seeking reliability and excellence in manufacturing, I highly recommend going with DECOWELL, where supply advantages and technological superiority meet for a seamless experience.